- Home

- Products

- Car Radiator Making Machine

- Aluminum Radiator Fin Forming Machine

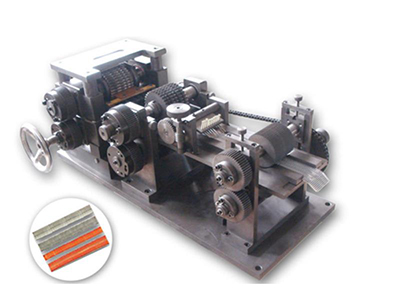

Aluminum Radiator Fin Forming Machine

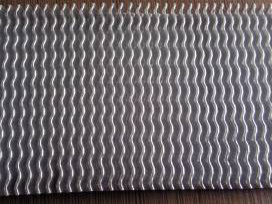

Description of Aluminum Radiator Fin Forming MachineThis fin forming machine is specially designed for forming aluminum foil coil into wave-type radiator fin continuously.

This fin forming machine offers PLC control, HMI operation, auto decoiling, feeding, forming, wave fixing and cutting, simple and highly efficient.

The machine adopts tooling quick changeable design for rolling different fins.

Main Technical Data of Aluminum Radiator Fin Forming Machine| Item | Data | |

| Blank material | Aluminum alloy foil | AA4343/AA3003/AA4343 or single foil |

| Foil thickness | 0.04~0.30mm | |

| Finished fin | Fin height | Based on rolling tool |

| Height tolerance | +0.03mm, - 0.01mm | |

| Fin height levelness | Less than 0.05mm | |

| Fin width | 8~200mm | |

| Fin pitch | 1.6~5.0mm | |

| Fin pitch tolerance | +/-0.10mm | |

| Machine capability | Foil feeding speed | 0-120m/min |

| Fin rolling speed | 1000-4000 corrugations per minute | |

| Fin cutting speed | Max. 60 times per minute | |

| Cutting tolerance | +/- 0 corrugation (on top of corrugation) | |

| Tooling | material | Forged high speed steel (W6) |

| Life | 250 million corrugations for laminated foil; 350 million corrugations for pure foil | |

| Total motor power | 5kW | |

| Compressed air source | 0.6MPa | |

| Machine dimension | About 6000 x 1500 x 2000mm | |

| Machine weight | About 2000kg | |

Plate Bar Radiator Fin Press Machine

For plate & bar radiators and heat exchangers, the aluminum fin is not rolled but punched. This fin press machine is special for punched type aluminum fins.

Being equipped with different kinds of dies, this machine can produce different kinds of aluminum fins for aluminum radiators, oil coolers, and other heat exchangers.

Fin shapes: Corrugated fin

Corrugated fin Offset fin

Offset fin Parallel louver fin

Parallel louver fin Perforated fin

Perforated fin Big pitch fin

Big pitch fin Blind vane fin (louvered)

Blind vane fin (louvered)

- Aluminum coil decoiler features mechanical expansion, active decoiling, and a capacity of 1000kg.

- Oil applying device, linked with oil tank, is used for applying lubricating oil onto aluminum fin.

- Automatic precision fin forming machine

- Servo counting and cutting device, HMI display, preset and auto-cut

- Aluminum alloy finished fin collecting table, with a steel frame

- Electric control system (integrated inside the fin forming machine)

| Item | Data |

| Aluminum fin data | |

| Applicable aluminum foil thickness | Max. 0.35mm |

| Max. Aluminum fin width | 300mm |

| Max. Aluminum fin height | 12mm |

| Min. Aluminum fin height | 1mm |

| Accuracy of punched fin height | +0.03 / -0mm |

| Fin punching press data | |

| Punching speed | 80~180 strokes/min |

| Motor power | 5.5kW |

| Noise level | Max. 80dB |

| Machine dimension | About 1320 x 800 x 1550mm |

| Machine weight | About 1600kg |

| Servo cutter data | |

| Cutting speed | 0~60 times /min |

| Cutting height | Max. 12mm |

| Cutting accuracy | +/-0.1mm |

| Compressed air | 0.5MPa |

| Machine dimension | Around 1200 x 700 x 1300mm |

| Machine weight | About 125kg |

| Foil decoiler data | |

| Applicable foil coil OD / ID | 1200mm / 470~510mm |

| Applicable foil coil width | 300mm |

| Machine dimension | About 2100 x 700 x 1100mm |

| Machine weight | About 750kg |

| Oil applying trough data | |

| Dimension | About 400 x 60 x 30mm |

| Weight | About 125kg |

Inquiry Form

English

English Español

Español Русский

Русский Português

Português Français

Français