- Home

- Products

- Metal Spinning and Flanging Machine

- Dished End Flanging Machine

Dished End Flanging Machine

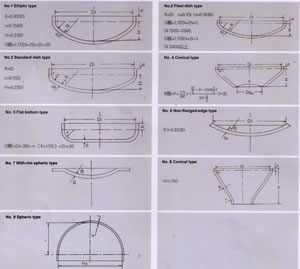

As the name suggests, this dished end flanging machine is designed for producing various kinds of dished ends through two steps, such as elliptical type, fleet dish type, conical type, spherical type, and so on. It is comprised of two machines: drum pressing machine and flanging machine.

Working Principle of Dished End Flanging Machine

The first step involves drum pressing machine. The piston of main cylinder moves up and down to drive upper tool to press the raw plate to become the required concave shape. The manipulator mounted inside the frame will move, rotate and incline the workpiece.

The second step is performed by the flanging machine. Adopting spinning principle, this machine will make blank workpiece from drum machine into elliptical end, dish end, spherical end, flat-bottom or taper-bottom end, etc. The structure is closed frame type, resulting in good rigidity. The spinning speed is stepless adjusted. Being of PLC control (Ormon from Japan), it is easy to operate.

Technical Parameters of Dished End Flanging Machine

1. Dished end diameter: 1m-10m (or customized)

2. Material wall thickness: 4-40mm carbon steel by cold flanging; 10-80mm carbon steel by hot flanging.

3. Detailed configuration and parameters depend on your exact dished end diameter and wall thickness.

Typical End Types

English

English Español

Español Русский

Русский Português

Português Français

Français