- Home

- Products

- Transformer Making Machine

- Tridimensional Core Transformer Making Machine

Tridimensional Core Transformer Making Machines

Our tridimensional core is especially designed for producing tridimensional core transformer which exhibits better performance, more reasonable structure, as well as less production cost. The tridimensional core is a new structure wound GRGO core with three columns of round cross section. By adopting this core, the transformer changes magnetic structure and significantly reduces no-load loss, no-load current, and noise level. Therefore, the running cost of transformer can be minimized. We can supply all machines and technology for manufacturing this kind of transformer.

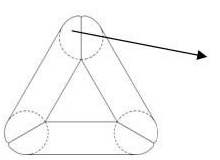

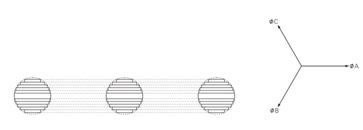

Tridimensional Core Structure

1. Our three-dimensional wound core is composed of three cores which are exactly the same.

2. Section of the three columns is round and lamination factor is up to 99%.

Technology Advantages

1. Wound core, no high resistance area

Each single core of the 3D core is wound with long CRGO strips, so the magnetic circuits are evenly distributed in any section. This prevents the formation of high resistance area due to laminating joints as well as magnetic flux waveform distortion at the joints.

2. After wound, the core will be annealed in vacuum annealing furnace.

3. No clamping tools

Because of up to 99% of lamination factor, the 3D core only needs to be taped with insulation paper. There is no need for clamping tools.

4. High automation

The whole production process of the core is accomplished by our transformer making machines automatically.

Characteristics

1. Optimized Magnetic Circuit Structure

Magnetic circuits of each phase are completely symmetrical and all phases are of equal circuit length. The overall length of the tridimensional core is shorter than any other core. Moreover, no-load current of each phase always achieves a complete balance, thus avoiding third harmonic generation.

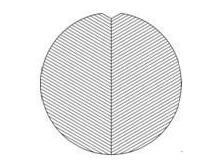

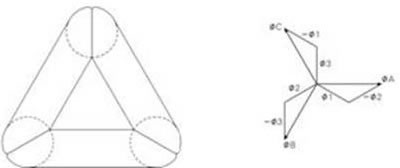

Magnetic Flow Vectogram of Tri-dimensional Core

Magnetic Flow Vectogram of Tri-dimensional Core Magnetic Flow Vectorgram of Traditional Laminated Core

Magnetic Flow Vectorgram of Traditional Laminated Core2. Drastically Reducing No-load Loss, No-load Current, and Noise Level

The no-load loss of the core transformers manufactured by our making machines is usually 30% less than that of traditional laminated core transformer.

The tridimensional core transformer fabricated by our machines offers up to 70% less no-load current than traditional transformer.

The noise level is reduced to approximately 7~ 10dB.

3. Unique Natural Ventilation and Radiation

The three yoke blocks of the wound core transformer occur at an angle of 60 degree to each other. After winding coils, a natural drawn chimney comes into being. The temperature difference between yoke upper and lower sections is of 30~40 ℃ and there must be air convection in the “drawn chimney” that will generate heat very quickly in the radial form. Hence, this decreases the temperature rise of transformer and increases its over-load capacity.

4. Compact Structure, Saving Copper, Steel and Oil

The core column has a round cross-section and the tridimensional core transformer created by our transformer machines is more compact, saving raw materials and reducing transformer sizes.

During processing of tridimensional wound core, the steel utilization reaches 100%, whereas the traditional laminated core gives 96% utilization.

The three dimensional core is 15%~20% less weight than laminated core with the same capacity. The weight of copper core is about 2%~3% less than that of laminated core.

5. Theft Deterrent

The tridimensional wound core made by our transformer making machine is a whole body and it can't be dismantled and the coil can't be removed. The core is applied with a theft deterrent. A 200kVA transformer is available with the weight of 650kg.

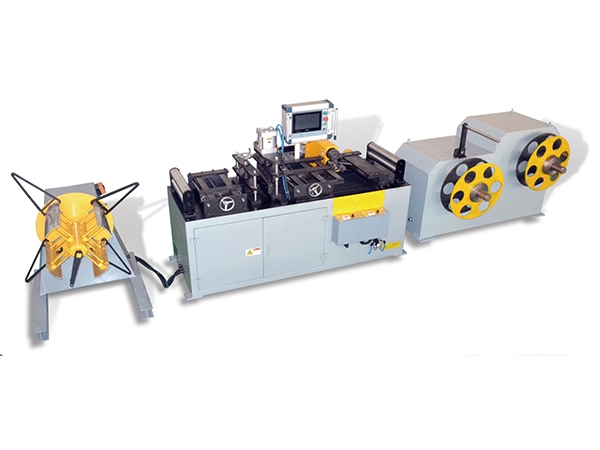

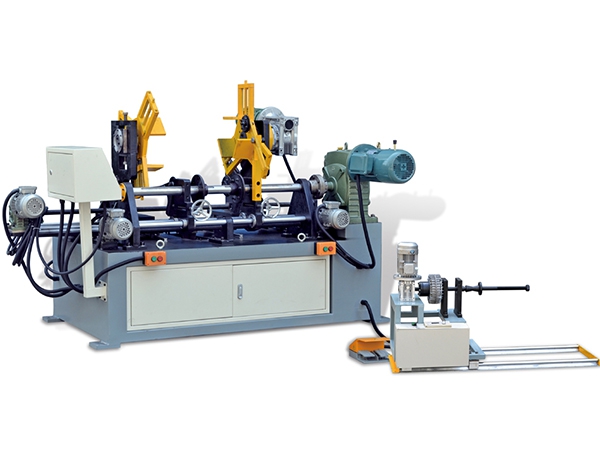

Machines for Tridimensional Core Transformer

Our company can offer both technology and machines for tridimensional core transformers. Please contact us for more details.

English

English Español

Español Русский

Русский Português

Português Français

Français