- Home

- Products

- Transformer Making Machine

- Transformer Core Winding Machine

Our core winding machine can be classified into three series. Customer can choose the product based on the actual production demand.

I. Heavy-duty Transformer Core Winding Machine

This range of product is applicable for winding cores for single phase or three-phase transformer (3-column or 5-column). The core section can be rectangle, trapezoidal or round. Composed of multi-head decoiler, feeding-rectifying-damping device, and main winding head (inverter control), the heavy-duty transformer core winding machine is applicable for winding toroidal cores for instrument transformer.

Technical Parameters of Core Winding Machine

| Item | TXJ-1 | TXJ-2 | TXJ-3 |

| Applicable transformer capacity (KVA) | 30-800 | 800-1600 | 1600-2000 |

| Torque of spindle (N·M) | ≥600 | ||

| Max. core weigh (kg) | 2000 | 2500 | 3000 |

| Max. core outer diameter (mm) | 750 | 900 | 1200 |

| CRGO strip width (mm) | ≤220 | ≤280 | ≤320 |

| Quantity of strips | 1-8 strips (8-heads material feeding stand) | ||

| Expanding range of feed head (mm) | 460-520 | ||

| Driving motor power (kW) | 9 | 13 | 13 |

| Winding speed (rpm) | 0-18 | ||

| Air pressure (MPa) | 0-0.6 | ||

| Counting method | Digital display, turns can be preset within the range of 1-9999 | ||

| Total weight (kg) | 4500 | 5000 | 5500 |

| Dimension (mm) | |||

| Feeding unit | 3700×840×2100 | ||

| Rectifying unit | 2065×800×1800 | ||

| Winding unit | 1860×1500×1730 | 1960×1650×1880 | 2060×1750×1980 |

| Floor area (mm) | 9000×2500 | 9000×2500 | 10000×2500 |

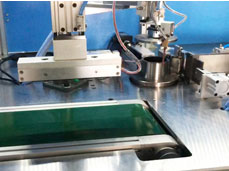

II. Transformer Core Winding Machine

This fully automatic toroidal winding machine is specially designed for winding toroidal cores made using CRGO electrical silicon steel. All the operations are controlled by Panasonic PLC control system with fully closed-loop control, including clamping, fixing, pressing, winding, cutting, welding, releasing.

5 Servo motors are equipped to drive the operations including

- Non-stop cutting

- Cutting down CRGO strips with max. thickness of 0.35mm (with reducer)

- Winding spindle (with reducer)

- Flapping & ejecting finished cores

- Feeding & clamping strip to pin on spindle

Main Features of Transformer Core Winding Machine

- 1. The operations are automatically made, including feeding, winding, cutting, welding, releasing.

- 2. PLC control and HMI panel makes the operations simple and convenient.

- 3. Adopting laser welding causes little or no damage to CRGO strip.

- 4. Motorized lift table can be adjustable to adapt to different toroidal core diameters.

- 5. Separate chillers are specially designed for control cabinet, and main electronic components.

- 6. Carbide cutting blade provides more than 3 million cuts

- 7. CRGO strips can be automatically decoiled.

Technical Parameter of Transformer Core Winding Machine

| Item | Specifications | |

| Suitable ribbon width | 8-80mm (customized) | |

| Suitable ribbon thickness | CRGO/CRNGO | 0.12~0.35mm |

| Permalloy | 0.1~0.35mm | |

| Suitable magnetic core ID | Min. 10 mm / Max. 160mm | |

| Max. magnetic core OD | 200mm (customized) | |

| Main spindle speed | Max. 3000rpm | |

| Magnetic core ID/OD tolerance | +/-0.5mm | |

| Magnetic core height tolerance | +/-0.1mm | |

| Total electric power | 1.4kW | |

| Max. ribbon reel weight | 200kg | |

| Machine dimension | About 1750 x 850 x 1600mm | |

| Machine weight | About 850kg | |

III Semi-automatic Toroidal Core Winding Machine

Features

1. The toroidal core manufactured with our semi-automatic toroidal core winding machine is generally used in transformers.

2. This product is equipped with automatic punching and cutting device.

3. Thanks to the adjustable guiding device and strip pressing device for the core winding machine, the winding tension and the winding precision can be perfectly controlled.

4. The pressing unit for the toroidal core winding equipment is designed with follow-up device. So the pressing unit will press on the core properly for good compacting degree.

5. Automatic core releasing device helps improve the working efficiency greatly.

6. Manual spot welding.

Technical Parameters of Semi-automatic Toroidal Core Winding Machine

| Item | TXJ-1A |

| Applicable strip thickness | 0.23-0.5mm |

| Applicable strip width | 20-200mm |

| Max. core OD | Φ350mm |

| Min. core ID | Φ30mm |

| Max. core weight | 800kg |

| Main driving motor | Inverter control, 3kW |

| Turns precision | ±0.1 turns |

| Winding speed | 0-200r/min |

| Machine dimension | About 1800×1400×1350mm |

| Machine weight | About 1900kg |

IV Toroidal Amorphous Core/Nanocrystal Core Winding Machine

The processing technology of the automatic core winder includes material feeding, internal welding, winding, cutting, and external welding. This toroidal amorphous core winding machine is composed of servo motor driving system, gear transmission unit, and fast-speed winding system. The related parameters, working conditions, as well as the machine failure, will be display on the HMI. In case there is material shortage or material defect, the PLC control system will send out the alarm automatically.

Technical Parameters of Amorphous/Nanocrystal Core Winding Machine

| Item | Specifications |

| Min. core inner diameter | 2.8-25mm (148mm) (by different machines) |

| Max. core outer diameter | 60 (165)mm (by different machines) |

| Applicable strip width | 2.8-10mm |

| Production speed | 8-12pcs/min |

| Core weight tolerance | Less than 1g |

| Wire coil weight | 3kg |

| Main winding servo motor power | Panasonic, 0.9-5kW (based on machine code) |

| Machine dimension | 1600×800×1400mm |

| Machine weight | 200kg |

| Control system | Panasonic PLC and HMI |

| Servo motor | Panasonic |

In addition to the said the products, the Beryllium-Mo alloy core winding machine and other special material core winding machines are also available from us. Luckily, we can produce automatic sorting & testing line, automatic gluing & packing line for finishing amorphous cores and nanocrystal cores.

-

Horizontal core winder

Horizontal core winder

-

Gluing machine

Gluing machine

-

Testing machine

Testing machine

Related Names

Transformer Core Winding Machine | Close Core Winding Machine | Toroidal Core Winding Machine | Core Winder | Open Core Winding Machine | Square Core Winding Machine | Rectangular Core Winding Machine

English

English Español

Español Русский

Русский Português

Português Français

Français