- Home

- Products

- Air Conditioner & Refrigerator Making Machines

- Fin Punching Press

Fin Punching Press

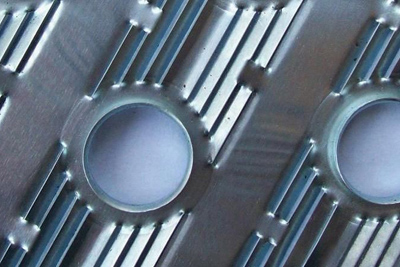

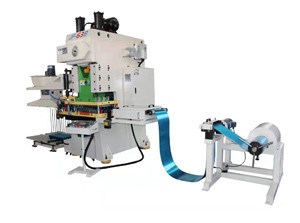

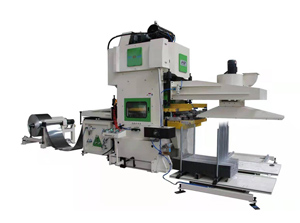

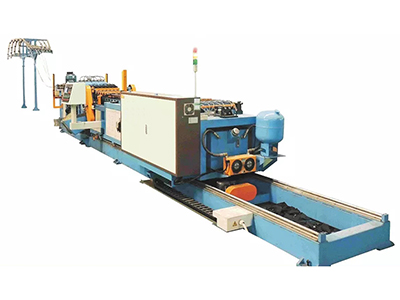

An automatic fin press line consists of an auto decoiler, lubricant oil applying device, high-speed punch press, and fin unloading & stacking device, which is suitable for processing aluminum or copper fin plates.

Configurations for Fin Punching Press:- Single-head aluminum foil decoiler allows for active decoiling and phototube control.

- Oil-through device equipped with an oil leveler

- Punching press with high-precision die and PLC-controlled pulling device

- In-die automatic lubrication device with waste oil collecting device

- Pneumatic fin sucking device

- Movable double-station fin collection device

- PLC control system displays the punching angle, stroke, hole number, stacking quantity, etc.

Main technical data of typical 45T open-type fin punching press

| No. | Item | Data |

| 1 | Nominal force | 450kN |

| 2 | Ram stroke | 40mm |

| 3 | SPM (Stroke for minute) | 120~200 / (150~250) per minute |

| 4 | Max. Die height | 210~270mm |

| 5 | Throat depth | 330mm |

| 6 | Slide bottom dimension | 300 x400mm |

| 7 | Size of working table | 660 x 850mm |

| 8 | Motor power | 5.5kW |

| 9 | Fin collecting height | Max. 650mm |

| 10 | Sucking length | Max. 1200mm |

| 11 | Size of aluminum foil | OD 850, ID 75mm, max. width 330mm |

| 12 | Compressed air | 0.6MPa, 0.4m3/h |

| 13 | Whole line dimension | 8 x 2m |

| 14 | Whole line weight | 8000kg |

Main Technical Data of Typical 63T Close-Type Fin Punching Press

| No. | Item | Data |

| 1 | Nominal force | 630kN |

| 2 | Ram stroke | 40mm |

| 3 | SPM (Stroke for minute) | 150~300 per minute |

| 4 | Max. Die height | 260~310mm |

| 5 | Min. Die height rise | 80mm |

| 6 | Slide bottom dimension | 1100 x890mm |

| 7 | Size of working table | 1600 x 900x115mm |

| 8 | Main motor power | 11kW |

| 9 | Total power | 19kW (max.) |

| 9 | Fin collecting height | Max. 720mm |

| 10 | Sucking length | Max. 1800mm |

| 11 | Size of aluminum foil | OD 1000, ID 150mm, max. width 560mm |

| 12 | Compressed air | 0.6MPa, 0.4m3/h |

| 13 | Whole line dimension | 10 x 3m |

| 14 | Whole line weight | 12000kg |

Inquiry Form

English

English Español

Español Русский

Русский Português

Português Français

Français