- Home

- Products

- Air Conditioner & Refrigerator Making Machines

- Return Tube Bending Machine

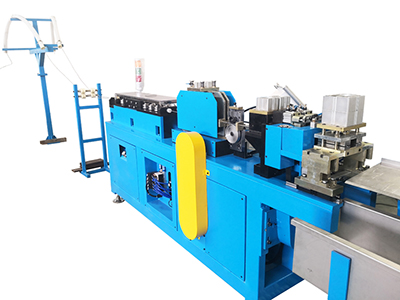

Return Tube Bending Machine

This return tube bending machine is specially designed for decoiling, straightening, bending, and cutting coil copper tubes into return U bends and crossover C bends, used in air conditioners and heat exchangers.

This return tube bending machine is comprised of coil copper tube pay-off device, straightening device, bending & cutting device, unloading device, hydraulic system, pneumatic system and PLC control system.

For coil copper tubes diameter not more than 9.52mm (3/8”), below 5-head pay-off device will be used, passive drive, without power.

| Item | Data |

| Suitable copper tube material | TP2 |

| Suitable copper tube reel size | Max. OD: Ф1100mm; ID: Ф130mm |

| Suitable copper tube diameter | Φ7.0mm / Φ9.52mm |

| Copper tube numbers | Max. 5 pieces |

| Cycle time | < 6s (for U bends) |

| U bend height error | ±0.5mm |

| Length error between two legs | Less than 0.5mm |

| Radius error | ±0.5mm |

| Pitch error (center distance between legs) | ±0.1mm |

| Straightness error | Curvature ≤3mm @L=1000mm |

| Flattening ratio at tube ends | Less than 5% |

| Thinning ratio at loop area | Less than 30% |

| Burr height at two ends | Less than 0.2mm |

| Finishing quality | No wrinkle, scratch, crack, dimple, bulge |

| Total electric power | 5kW |

Inquiry Form

English

English Español

Español Русский

Русский Português

Português Français

Français