- Home

- Products

- Air Conditioner & Refrigerator Making Machines

- Bundy Tube Straightener & Cutter

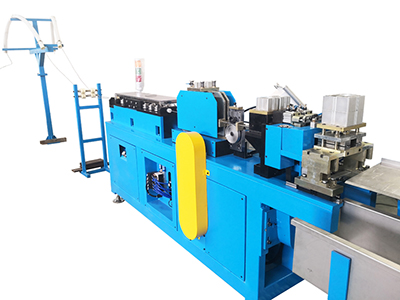

Bundy Tube Straightener & Cutter

This Bundy tube straightener & cutter is for straightening coil Bundy tubes and capillary copper tubes, detecting length and burrless cutting automatically.

This machine adopts pull-apart cutting technology which is the most advanced cut-off method in the world, which eliminates or minimizes tube ID reduction that could occured and brings burr-less cutting result as well.

Main Features of Bundy Tube Straightener & Cutter- Servo feeding, stable and high re-positioning precision

- One time cutting two pieces, high efficient

- Adopting pull-apart technology, less tube end ID reduction ratio

- Orbited cutter with spray lubricant, burrless cutting

- PLC control, high automation—auto feed, auto cut, auto counting, auto alarm.

Main Technical Data of Bundy Tube Straightener & Cutter

| Item | Data |

| Suitable tube | Coil copper tube TP1/2 (M/M2) / Bundy tube |

| Suitable tube diameter range | Ф4.6~Ф10.6mm |

| Suitable tube wall thickness | 0.5~1.0mm |

| Cutting length range | 40mm ~ unlimited |

| Pay-off device | 1 |

| Tube coil reel size | OD: 400~600mm; Weight: max. 100kg |

| Cutting pipes one time | 2 |

| Cutting speed | 8 cuts per minute (@L=1000mm)* |

| One-time feeding stroke | Continuous feeding, no length limit |

| Cut-to-length tolerance | ≤0.3mm /1000mm |

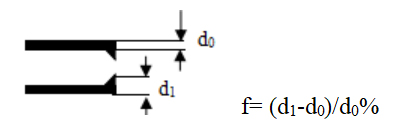

| Tube mouth ID reduction ratio | f < 20% * |

| Length difference among two pieces | ≤0.5mm |

| Roundness of cut tubes | Non-roundness ≤3% |

| Surface condition after cut | No apparent scratch, drawing marks; no burrs |

| Compressed air | 0.5-0.7MPa |

| Total electric consumption | 1.0kW |

| Main machine dimension | 2600 x 1200 x 1500mm |

| Pay-off device dimension | 2000 x 1000 x 2000mm |

* 1-When cutting length is less than 100mm, there will be no pre-stretching function.

* 2- Tube end ID reduction ratio means:

Inquiry Form

English

English Español

Español Русский

Русский Português

Português Français

Français