- Home

- Products

- Air Conditioner & Refrigerator Making Machines

- CNC Copper Tube Bender

CNC Copper Tube Bender

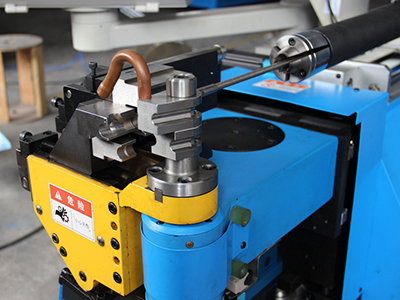

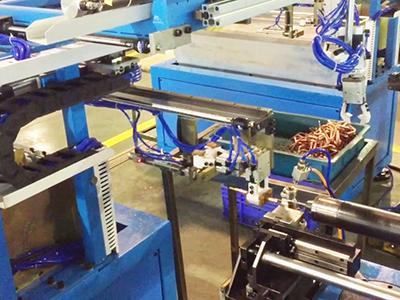

Main Features of CNC Copper Tube Bender- The tube bender frame and body adopt keel structure to ensure high intensity, rigidity, and stability.

- The bending head is designed in an integral box structure and the bending arm adopts a precise teeth chain as transmission, offering high precision.

- Special clamping structure ensures enough clamping force, not to damage workpiece.

- The core rod is of universal joint type, exempting from lubrication.

- Machine has self-testing function for detecting original of X and Z axis and dead point alarming.

- 8” LCD displayer, integrative antifouling keyboard

- CNC controller can save 400 units programs for 400 products, G-M code, with RS232 interface

- Program has auto-calibration function for bending angle and length, auto counting, auto alarming, power-off memory.

| Item | Data | ||

| Suitable bending tube diameter | Copper/aluminum | Max. 20mm | |

| Carbon steel | Max. 16mm | ||

| Suitable tube wall thickness | Copper/aluminum | Max. 1.5mm | |

| Carbon steel | Max. 1.0mm | ||

| Max. bending angle | 0- 200º | ||

| 3D rotating angle | 360º | ||

| Max. bending radius | R80mm | ||

| Min. bending radius | R10mm | ||

| Max. workpiece length | 1800mm (through-type) | ||

| Feeding stroke | 0-1200mm | ||

| General bending efficiency | 2.2 sec. per bend | ||

| Feeding speed | 1-1200mm/sec. | ||

| Rotating speed | 0-600 º/sec. | ||

| Bending speed | 0-300 º/sec. | ||

| Re-positioning precision | Feeding axis | ±0.05mm | |

| Rotating axis | ±0.05º | ||

| Bending axis | ±0.05º | ||

| Servo motor power | Feeding axis | 1.5kW | |

| Rotating axis | 0.75kW | ||

| Bending axis | 3.0kW | ||

| Pneumatic pressure | 0.5-0.7MPa | ||

| Power supply | 380V, 3Phase, 50Hz | ||

| Machine dimension | 2500 x 620 x 1300mm | ||

| Weight | About 1200kg |

||

Inquiry Form

English

English Español

Español Русский

Русский Português

Português Français

Français